China Linear Actuator Manufacturers Factory Suppliers

We are a professional Gas Springs factory, providing electric linear actuator, heavy duty linear actuator, high speed linear actuator, mini linear actuator, 24v linear actuator, 12v linear actuator etc.

Linear Actuator are mainly made of high-quality stainless steel materials and are widely used in automobiles, beds, machines, mechanical equipment, ships, containers, etc. This product has been carefully designed and tested for excellent performance and usability.

Company Advantages

Professional Team

We have hundreds of professional and technical personnel who can provide you with professional services.

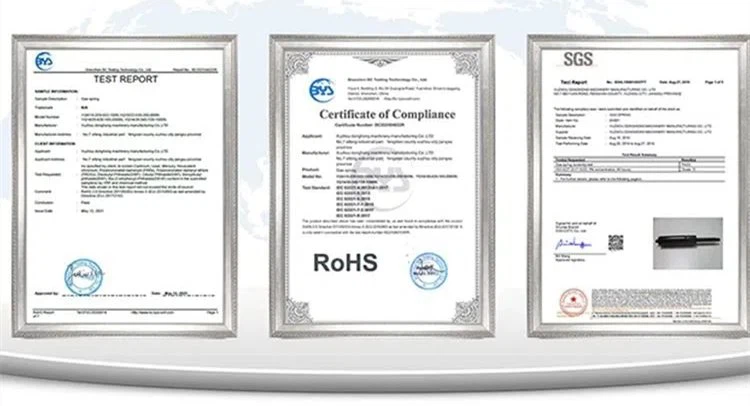

Multiple Certifications

We have ISOTS 169492009, CCC, SGS and CE certifications, ensuring the quality of our products.

Products are Well Received

Our products are globally exported, reaching various countries and regions, and have garnered widespread acclaim from satisfied customers.

Competitive Price

We provide competitive price and excellent customer service for all our customers. We also can offer different discounts based on your order quantity.

Customized Services

We can provide customized services to meet customers' special requirements. lf you have any special request, pls send us the details.

24-hour Online Customer Service

Our customer service is available online 24 hours a day. After receiving the service information or feedback from the customer, we will reply and address the feedback in the shortest time.

Introduction to Linear Actuator

A linear actuator is a device that creates linear motion, or motion in a straight line. This is different from the circular motion of a conventional electric motor.

Linear actuators can be used for lifting, dropping, sliding, or tilting machines or materials. They provide efficient and maintenance-free motion control.

Linear actuators can be powered by electric AC and DC motors, or by hydraulics and pneumatics. They can be used with simple wiring, and are easy to handle because they don't use hydraulics or pneumatics.

Product Advantages

● Linear Actuator has smooth movement with uncompromising design.

● Linear Actuator is a reliable and durable actuator system that is easy to install.

● The Linear Actuator actuator has low-noise and low standby power consumption.

● Linear Actuator Servo motors allow the motor to exchange information with and to be controlled by an external control system.

Types of Linear Actuator

The linear actuator produced by our company include the following types:

● Electric Linear Actuator

An electric linear actuator is a device that converts a motor's rotary motion into linear motion. It's made up of a motor, gears, and a worm and tube motion mechanism. The actuator uses a DC or AC motor, gears, and a lead screw to push the main rod shaft.

Electric linear actuators are often used when applications require lifting, pulling, pushing, or tilting with force. They're ideal for applications that require simple, safe, and clean movement with smooth motion control and accurate precision.

● Heavy Duty Linear Actuator

Heavy duty linear actuators are used in industrial settings that require linear motion, such as automotive manufacturing, robotics, and food and beverage processing. They have a higher force capacity than other actuators, and are more precise and accurate.

Heavy duty linear actuators are made up of a DC motor and control devices, and a telescopic rod that moves in a straight line. They usually work with 12, 24, 36, or 48 volts DC voltage, and can be operated with a remote control switch kit.

● High Speed Linear Actuator

A high speed linear actuator's maximum speed can vary depending on its size, capacity, drive mechanism, and load. On average, high speed linear actuators have a maximum speed of 30–500 millimeters per second.

High Speed Linear Actuators are used in many industrial settings, including automotive manufacturing, process industries, food and beverage processing, material handling, and robotics.

● Mini Linear Actuator

A mini linear actuator is a small, electric actuator that uses a 12 volt DC motor. They are compact and can be used for home automation.

Mini Linear Actuators convert rotational motion into linear motion, which can be used for lifting, dropping, sliding, or tilting. They are ideal for applications that require tilting, lifting, pulling, or pushing with pounds of force.

● 24V Linear Actuator

A 24-volt linear actuator is a device that allows movement in a robot. They are a good option for demanding applications where an alternative to hydraulic or air cylinders is needed. 24 volt dc linear actuators draw a lower current than 12V actuators. Current reduction has a number of advantages, such as saving costs on wiring and electrics and reduced losses in a conductor.

● 12V Linear Actuator

A 12V linear actuator is a device that pushes or pulls something in a straight line. It converts rotational motion into linear motion to lift, lower, slide, or tilt materials or machines.

12V linear actuators are powered by 12 volt DC voltage sources. They are used when precise movement is required within a limited space and with lighter payloads. 12V linear actuators are compatible with various power sources, including batteries, making them ideal for remote or off-grid applications.

Advantages of Linear Actuator

Electric Linear Actuator

Electric linear actuators can improve the efficiency, reliability, productivity, controllability, and performance of the working process. They can also reduce the engineering components, installation time, complexity, and overall costs.

Electric linear actuators have many advantages, including:

● Programmable: They can work with an external or integrated electronic control box.

● Accurate: They offer a high level of precision in both movement and control.

● Customizable: They offer custom speeds, stroke lengths, and applied forces.

● Quiet: They are quieter than pneumatic and hydraulic actuators.

● Maintenance-free: They have a long life span and are energy efficient.

● Low operating cost: They can provide cost savings in many cases.

● Less maintenance: There's very little requirement for regular maintenance as there's no risk of fluid leakages.

● Controlled acceleration and speed: They can be predicted.

Heavy Duty Linear Actuator

Heavy duty linear actuators have several advantages, including:

● Resistance: They are resistant to corrosion, vibrations, and extreme temperatures.

● Accuracy: They have digital position feedback, which improves accuracy.

● Quiet: They are quiet and don't produce vibrations or noise.

● Maintenance: Electronic linear actuators are self-lubricated and have fewer moving parts, which reduces maintenance costs.

● Control: They offer precise control of linear motion, making them ideal for applications that require repetitive motion and precise positioning.

● Versatility: They can be used in a variety of applications, including robotics, industrial automation, and consumer products.

High Speed Linear Actuator

High-speed linear actuators have several advantages, including:

● Durability: They are robust and have fewer moving parts, which makes them quieter.

● Ease of integration: They can be easily integrated into existing control systems and usually run on lower voltages.

● Simple design: They have a simple design with minimal moving parts.

● High speeds: Some high-speed linear actuators can reach speeds of up to 2,000 millimeters per second or more.

Mini Linear Actuator

Mini linear actuators have several advantages, including:

● Compact design: Mini linear actuators are compact and have a low profile, making them ideal for applications where space is limited.

● Long stroke: A small linear actuator with a long stroke can provide a longer range of motion in a compact package. This can be useful in applications where space is limited or where a longer stroke is needed for precise positioning.

● Quiet operation: Mini linear actuators don't produce noise or vibrations, and provide quieter performance in all environments.

● Low maintenance: Electronic linear actuators are self-lubricated with less moving parts, which help reduce the overall maintenance costs.

● Energy efficient: Mini linear actuators are highly efficient users of energy.

● Long life: Mini linear actuators have a long life, making them a perfect solution for manufacturing operations.

● Safe and predictable: Mini linear actuators can be more safe and predictable in an emergency stop application since they don't depend on trapped air to hold the cylinder in place.

24V Linear Actuator

24V linear actuators have several advantages, including:

● Low current draw: 24V actuators draw less current than 12V actuators, which can reduce conductor losses and save on wiring and electric costs.

● Thin-wire applications: 24V actuators are ideal for thin-wire applications.

● Easy installation: 24V actuators are simple to incorporate into new or existing machine designs, requiring only a few wires. They also require less maintenance because they don't contain hazardous fluids.

● Versatility: Linear actuators can be used in a variety of applications, including consumer products, robotics, and industrial automation.

● Space-saving design: Linear actuators are compact and have a low profile, making them ideal for applications where space is limited.

● Quieter than pneumatic and hydraulic actuators: Electric linear actuators provide complete control of motion, offering custom speeds, stroke lengths, and applied forces.

12V Linear Actuator

12V linear actuators have several advantages, including:

● Variable speed control: 12V linear actuators provide pulse width modulation for variable speed control.

● Analog and digital feedback: 12V linear actuators have multiple options for analog and digital feedback.

● Low voltage switching: 12V linear actuators have low voltage switching options that can connect directly to programmable PC or PLC controllers.

● Easy installation: 12V linear actuators are easy to install because they only need a few wires to function.

● Maintenance-free: 12V linear actuators don't require maintenance because they don't have leaky, hazardous fluids.

● Environmental protection: 12V linear actuators provide unrivaled environmental protection.

● Small size: 12V linear actuators are small-sized and powerful.

● Electro mechanical motion: 12V linear actuators use a small DC gear motor with a screw-drive and gears to provide electro mechanical motion.

Applications of Linear Actuator

Electric Linear Actuator

Electric linear actuators are used in applications that require accurate and metered motion control. They can be used to push or pull with the same force, and can be used for lifting, lowering, sliding, adjusting, and tilting objects.Here are some applications for electric linear actuators:

● Material handling: A universal need for all manufacturing operations.

● Robotics: Used to control repetitive movements, including the acceleration rate and the force applied.

● Food and beverage manufacturing: Linear actuation can create motion for food and beverage applications, from station cleaning to conveyors.

● Window automation: Linear actuators can be used to adjust and tilt objects.

● Agricultural machinery: Linear actuators can be used in agricultural machinery.

● Solar panel operation: Linear actuators can be used in solar panel operation.

● Cutting equipment: Linear actuators can be used in cutting equipment.

● Valve operation: Linear actuators can be used in valve operation.

Heavy Duty Linear Actuator

Automotive manufacturing, Process industries, Food and beverage processing, Material handling, Robotics.

Heavy duty linear actuators are also used in many other industries, including:

● Medical equipment

● Agriculture machinery

● High-voltage switch gears

● Train and bus doors

● Factory processes and assembly machinery

● Some other applications of Heavy duty linear actuators include: Window automation, Solar panel operation, Cutting equipment, Valve operation, Machine tools, Lawnmowers, Printing, Construction, Defense, Aerospace, Industrial machinery, Clean energy.

High Speed Linear Actuator

High Speed Linear Actuators are devices that convert rotational motion into linear motion. They can be used to lift, lower, slide, or tilt materials or machinery.

Here are some applications for High Speed Linear Actuators:

● Material handling: This is a universal need for every type of manufacturing operation.

● Robotics

● Food and beverage manufacturing

● Window automation

● Agricultural machinery

● Solar panel operation

● Cutting equipment

● Valve operation

Mini Linear Actuator

Mini Linear Actuators can be used for a variety of applications, including:

● Aerospace: Opening and closing valves, tracking solar panels, opening and closing compartments, locking and securing compartments, adjusting seats and beds, robotic arms, extending and retracting landing gear

● Defense and military: Weapon operation, transport, and logistics

● Industrial automation: Robotics, assembly lines, material handling

● Consumer products: Appliances, electronic devices

● Other: Material handling, food and beverage manufacturing, window automation, agricultural machinery, solar panel operation, cutting equipment

24V Linear Actuator

24V linear actuators can be used in many applications, including:

Home applications: Can be used for remote control, centralized control, or automatic control

Industrial applications: Can be used for lifting platforms, tables, window openers, door openers, massage couches, electrical appliances, medical chairs, medical beds, and micro-devices

Robotics: Can be used to control repetitive movements, including the acceleration rate and the force applied

Food and beverage manufacturing: Can be used for PET bottle production, filling and labeling systems, and robotic applications like milking robots

Material handling: A universal need for every type of manufacturing operation

Window automation: Can be used for window automation

Agricultural machinery: Can be used for agricultural machinery

Solar panel operation: Can be used for solar panel operation

Cutting equipment: Can be used for cutting equipment

Valve operation: Can be used for valve operation

12V Linear Actuator

12V linear actuators are devices that convert rotational motion into linear motion. They can be used to push, pull, lift, and lower machinery or materials. 12V linear actuators are ideal for applications that require precise movement within a limited space and with lighter payloads.

Here are some applications for 12V linear actuators:

Home

Adjustable furniture, recliners, and adjustable beds

Industry

Heavy machinery, construction equipment, elevators, automobiles, sliding doors and windows, and automated assembly lines

Robotics

Controlling repetitive movements, such as the acceleration rate and the force applied

Working Principle of Linear Actuator

The working of the actuator starts with the rotor and the stator assemblies. These assemblies facilitate the primary and secondary workings of the motor.

01

Voltage is applied to the stator assembly, which acts as the primary workings. This voltage is then converted into a current. This current is shunted into the rotor assembly, which acts as the secondary workings.

02

The working of the rotor and stator assemblies, helps create a field, which facilitates motion.

03

The motion created by the motor is then passed to the cylinder. Here, cylinder interacts with the limit switch to convert this motion into a linear one.

04

The cylinder is turned by the gears, which helps promote the linear motion.

05

Component of Linear Actuator

Motor

This is one of the most important components of linear actuators, which actually makes the motion. A 12 volt DC motor is used, which interacts with other parts of the actuator to deliver the movement.

Limit Switch

This component controls the motion of the device. It stops the movement, when triggered.

DC Brushes

The current is conveyed between the stationary wires by the DC brushes. They are responsible for bringing the current into the actuators.

Lead Screw

The main role of lead screws is to convert the rotational motion into linear motion. They are attached in the cylinder, and travel up and down, which facilitates the linear motion.

Gears

They act as a connector between the motor and the lead screw, which helps them in a free movement.

Cylinder

The motion, which is created by the motor, makes the parts of the cylinder to move to and fro. The cylinder does not move itself, however, the parts inside it do.

Maintenance Tips for Linear Actuator

Here are some tips for maintaining linear actuators:

Regular maintenance: Perform regular maintenance checks. This includes checking the mounting bolts, nuts, washers, and screws for damage and tightness. You should also confirm the handwheel is operating correctly and that there is physical movement of the valve.

Lubrication: Most manufacturers emphasize the importance of proper lubrication. This can help increase the life of various components like nuts and bolts.

Operate below max rated force: For maximum lifespan, it's recommended to operate your actuator as far below the max rated force as possible. If you require a high force, consider moving up to a higher gearing ratio.

Reduce voltage: A simple way to lower the speed of a linear actuator is to reduce the voltage at which you drive it.

Use limit switches: You can try purchasing an external limit switch that, when depressed, will stop the actuator.

Precautions of Linear Actuator

Improper use of a linear actuator can lead to poor performance, danger to the operator, and damage to the actuator.

Here are some precautions for linear actuators:

Inspect before use: Check that the power supply line and signal lines are not damaged or loose. Also, make sure the actuator, cylinder, controller, and driver are not mounted loosely.

Avoid magnetic objects: Magnetic objects placed close to the actuator can cause it to operate suddenly, which can be dangerous and damage equipment.

Avoid side loading: Do not side load the actuator.

Use within limits: Only use the actuator within the specified working limits.

Stop immediately: Stop the actuator immediately if anything unusual is observed.

Avoid hard objects: Avoid using hard objects to impact valve electric actuators.

Certifications

Our products all have passed test of ISOTS 169492009, SGS, CCC and CE certification. The quality of our products is highly praised by customers.

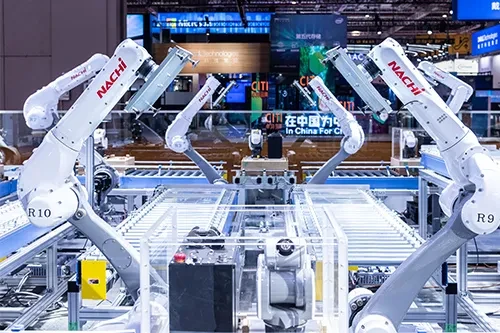

Our Factory

We have professional production lines and advanced equipment.

Frequently Asked Questions

Q: What are the disadvantages of Linear Actuator?

Q: What does Linear Actuator for Recliner Chair do?

Q: Why Linear Actuator cannot work?

Q: Is Electric Linear Actuator safe?

Q: What is the lifespan of a linear actuator?

Q: What are the benefits of Linear Actuator for Standing Desk?

We're professional linear actuator manufacturers and suppliers in China, featured by quality products and competitive price. If you're going to buy discount linear actuator made in China, welcome to get free sample from our factory.

Linear Actuator for Door Opener, gas door shock, hood gas struts